Foreign AGV manufacturer characteristics and IKV Industry 4.

Release date: 2016-08-20 17:33 Clicks: Author: admin

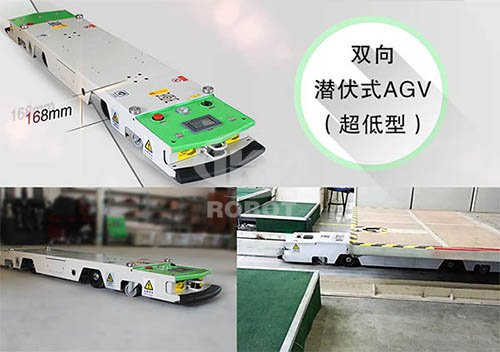

Nanchang IKV industrial robot is a robot unique technology as the core, committed to digital intelligent high-end equipment manufacturing high-tech listed companies. AGV domestic market in the development stage, intelligent AGV manufacturers began to focus on R & D investment, increase domestic manufacturers of AGV performance requirements. For foreign AGV manufacturers each have characteristics which have nothing to learn from domestic AGV manufacturers?

1. the characteristics of the Japanese model is: AGV manufacturers for the development and mass production of high-AGV products targeted by the company's engineering solutions on society to design complete systems AGV industry application needs. This model in China is relatively common practice, but due to the industry-standard products vary according to each enterprise customer unit, or user to use the budget, the skill levels are uneven, so the final AGV overall reliability and feasibility of the program entirely "not by spectrum "!

2. The European model is characterized by: System specific design and manufacturing, engineering package of technical resources, AGV manufacturers and users need all done by AGV manufacturers themselves. This mode is good, but the industry specializing in surgery, on the one hand AGV system integration overall cost is very expensive, on the other hand very long development cycle, it has always been a "low bid" in the domestic market is clearly not applicable.

3. The American model is: basically does not produce normal AGV products, projects need AGV products are usually sourced from engineering solutions company, and then a second design, manufacture supporting peripherals, complete turnkey projects. In theory, this model is a very good model, but in China, "the world is a big copy technology" builders often want their enterprise product line "High," and also do not want to bear the cost of the risk posed by the pre-development Therefore each third-party technology companies closed their own way are reluctant to put too much of the pre-development costs, and ultimately unable to achieve data interoperability, so this mode it is not feasible in the short term China.

Hope that a large number of case studies, according to Ike Weir industry needs to develop an open software platform will be completed (AGV car + Process management + software + data exchange platform + Intelligent Peripherals) logistics process chain integration, build a belongs AGV smart "ecosystem", the establishment of AGV logistics nodes as the main industry 4.0 device management platform to advance and choose more suitable for their products by the user, it has the advantage to choose a more suitable process and pricing based on the platform product, customer oriented projects to promote faster and provide a standard, manufacturers do not have to worry about the associated technical compatibility issues, and secondly to reduce intermediate trading links sales more secure, we believe it will bring about huge changes in the manufacturing sector.

IKV Will provide custom manufacturing production: industrial robots, networking card, Industry 4.0 cards, automatic welding robots, automatic loading and unloading, automatic spray systems, automatic polishing, industrial controllers, IOT communication card, A / D data module, PEC and other high-tech products. For details, please contact our 24-hour hotline: 0791-88121058